Plycem High Performance Non-Combustible Subfloor Panels

UL Classified Fiber Cement Structural Panels for 1-Hour and 2-Hour Fire-Rated Floor Assemblies | ASTM C1186-08 Type A Grade I Certified | Cost-Effective Alternative to USG Structo-Crete for Multifamily and Commercial Construction

UL R15140

Fire-Rated Assemblies

ASTM C1186-08

Type A, Grade I

ISO 8336:2018

Category A, Class 1, Level 1

ASTM E-84

Class A Fire Rating

ISO 9001:2015

Quality Management

ISO 14001:2015

Environmental Management

ISO 45001:2018

Safety Management

Product Overview: Plycem High Performance Subfloor System

Plycem High Performance Subfloor is a non-combustible fiber cement structural panel manufactured by The Plycem Company (part of Elementia Group, Mexico) specifically designed for use in fire-rated floor assemblies in Type I and Type II construction. The product is UL Classified under file number R15140 and meets ASTM C1186-08 Type A, Grade I specifications for fiber-reinforced cement board.

Primary Applications: Multi-story multifamily residential buildings (wood-frame over concrete podium), commercial structures requiring non-combustible flooring, hotels, office buildings, institutional facilities, and modular/prefab construction where fire-rated assemblies are mandated by building codes.

Key Product Features & Applications

Plycem High Performance Subfloor combines innovative engineering with practical installation benefits for modern construction projects.

SAFE

Non-combustible, fire-rated

DURABLE

Long-lasting performance

FAST INSTALL

800-1000 SF/day

CLEAN

Dry installation process

COST-EFFICIENT

65-70% savings vs competitors

Key Technical Certifications

Cost Savings Documentation: Plycem pricing: $79-88/panel CIF Long Beach (Cost, Insurance, and Freight — includes product, ocean freight, and insurance to Long Beach port). USG Structo-Crete retail pricing: $255-270/panel (source: New England Gypsum, Tamarack Materials, February 2026). Calculated savings: 65-70% material cost reduction. For a 10,000 SF floor (≈320 panels): Plycem ≈$26,880 vs Structo-Crete ≈$83,840 — save over $56,000 per floor.

Key Advantages

65-70% Cost Savings

vs. USG Structo-Crete. Material cost reduction of $56,000+ per 10,000 SF floor. Plycem: $79-88/panel (CIF) vs Structo-Crete: $255-270/panel.

In Stock, Long Beach CA

1,500+ panels ready for 0-3 day delivery. No 2-6 week lead times. Eliminate schedule risk and carrying costs.

1-Hour & 2-Hour Ratings

UL Classified for designs H502, H504, H511, U449, U487. For wood and steel joist floor/ceiling assemblies.

Comparative Analysis: Plycem vs. Competitive Non-Combustible Subfloor Options

This comparison evaluates Plycem against the primary market alternative (USG Structo-Crete) and traditional poured concrete systems based on performance, cost, and installation characteristics. View full comparison & pricing

| Characteristic | Plycem Subfloor | USG Structo-Crete | Poured Gypsum Concrete |

|---|---|---|---|

| Material Type | Fiber-reinforced Portland cement board | Fiberglass-reinforced cementitious panel | Gypsum-based cementitious slurry |

| Combustibility | Non-combustible (ASTM E136) | Non-combustible (ASTM E136) | Non-combustible |

| Fire Rating Capability | 1-hour and 2-hour (per UL designs) | 1-, 1.5-, and 2-hour (per UL designs) | Up to 3-hour (thickness dependent) |

| ASTM E-84 Flame Spread | 0 | 0 | 0 (inherently non-combustible) |

| ASTM E-84 Smoke Development | 0 | 0 | 0 |

| Typical Cost per 4'x8' Panel | $79-88 (CIF Long Beach) | $255-270 (retail) | $90-120 (material + labor equivalent) |

| Lead Time (West Coast) | 0-3 days (in stock Long Beach) | 2-6 weeks (regional availability varies) | 7-14 days (scheduling + cure time) |

| Weight (20mm / 3/4" equivalent) | 67.9 kg (149.6 lbs) per 4'x8' panel | 77.1 kg (170 lbs) per 4'x8' panel | ~136 kg (300 lbs) per 4'x8' area at 1.5" thick |

| Moisture Resistance | Excellent (ASTM C1186 Type A) | Good (ASTM C1185 Type B) | Moderate (requires curing protection) |

| Installation Method | Mechanical fastening (screws) | Mechanical fastening (screws/staples) | Pumped and leveled |

| Installation Speed | Fast (~800-1000 SF/day, 2-person crew) | Moderate (~700-900 SF/day) | Slow (pour + 48-72 hour cure) |

| Sound Transmission Class (STC) | 50-55 (in tested assemblies) | 52-58 (in tested assemblies) | 55-65 (mass-dependent) |

| Impact Insulation Class (IIC) | 50-55 (with underlayment) | 50-65 (with underlayment) | 60-70 (mass advantage) |

Explore Product Information

Find the technical data you need for your project.

Technical Specifications

Complete material composition, mechanical properties, and dimensional data for all panel variants.

Fire & Code Compliance

UL fire-rated assembly data, ASTM E-84/E-136 testing, IBC 2021 and California Building Code compliance.

Installation Guide

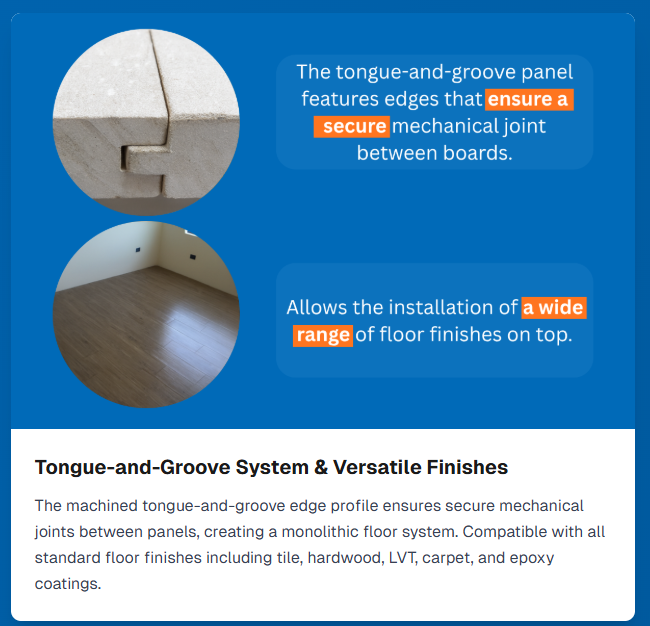

Framing requirements, fastening schedules, T&G system, tools, safety, and compatible floor finishes.

Pricing & Availability

Volume pricing tiers, competitive comparison, cost-benefit analysis, and lead times.